- What Are Common Causes of .NC Files Lost or Failure?

- How to recover lost .NC files?

- Programs to recover .NC files

- How to open file with .NC extension?

What Are Common Causes of ".NC" Files Lost or Failure?

There can be several common causes of ".NC" files being lost or experiencing failure. Some of these causes include:

- Accidental deletion: Human error such as accidentally deleting the ".NC" files can lead to their loss.

- System crashes: Sudden system crashes or power failures can interrupt the saving or processing of ".NC" files, resulting in their failure or loss.

- Software or hardware issues: Problems with the software or hardware being used to create or access ".NC" files can cause failures or corruption.

- Virus or malware attacks: Malicious software can infect and corrupt ".NC" files, making them inaccessible or causing them to be lost.

- File system errors: Errors within the file system, such as disk errors or file corruption, can result in ".NC" files becoming damaged or lost.

- Improper file transfer: If ".NC" files are not transferred correctly or interrupted during the transfer process, they may become corrupted or lost.

- Storage media failures: Issues with the storage media, such as hard drive failures or damage to external storage devices, can lead to the loss or failure of ".NC" files.

- Incompatible software versions: Using incompatible software versions or attempting to open ".NC" files with unsupported software can cause failures or errors.

- Network issues: Problems with network connectivity or interruptions during file transfers can result in ".NC" files being lost or corrupted.

- User mistakes: Mistakes made by users, such as accidentally overwriting or modifying ".NC" files, can lead to their loss or failure.

How to recover lost ".NC" files?

Sometimes while working with a computer, laptop or other stationary or mobile devices, you may encounter various bugs, freezes, hardware or software failures, even in spite of regular updates and junk cleaning. As a result, an important ".NC" file may be deleted.

🧺 How to Recover Files and Folders After Sending Them to the Recycle Bin and Deleting? (Windows 11)

By no means should you think that the only way to recover a ".NC" file is always to create it once more.

Use programs for recovering ".NC" files if a file was lost after accidental or deliberate deleting, formatting the memory card or the internal storage, cleaning the storage device, after a virus attack or a system failure.

Programs to recover ".NC" files

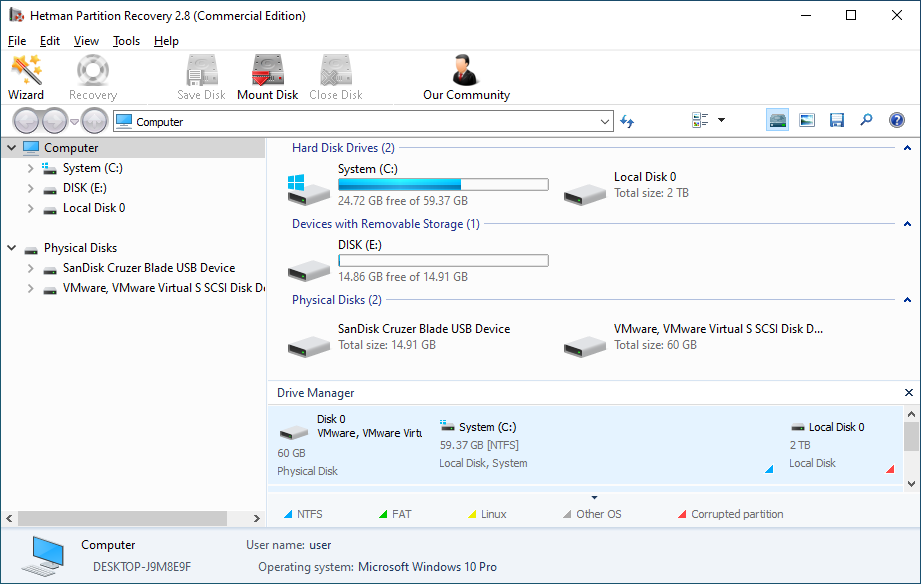

Looking for a way to get files back? In cases when files were deleted and they cannot be restored by using standard operating system tools, use Hetman Partition Recovery.

Follow the directions below:

-

Download Hetman Partition Recovery, install and start the program.

-

The program will automatically scan the computer and display all hard disks and removable drives connected to it, as well as physical and local disks.

-

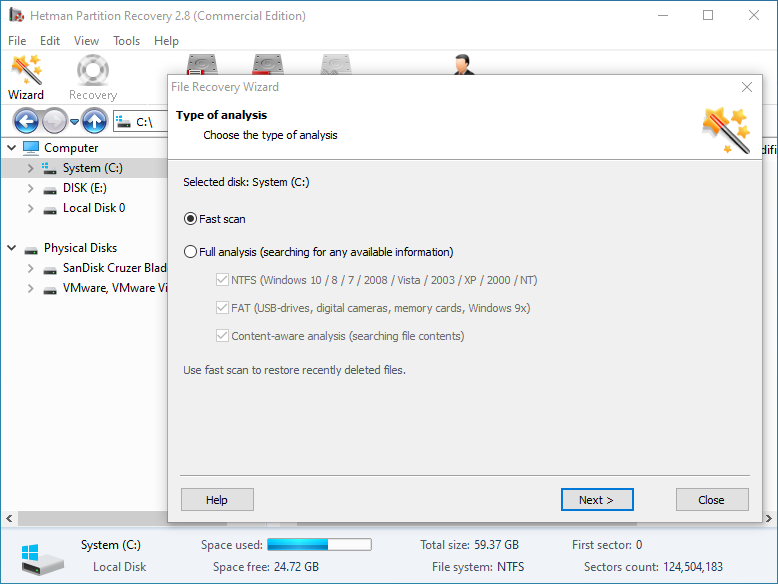

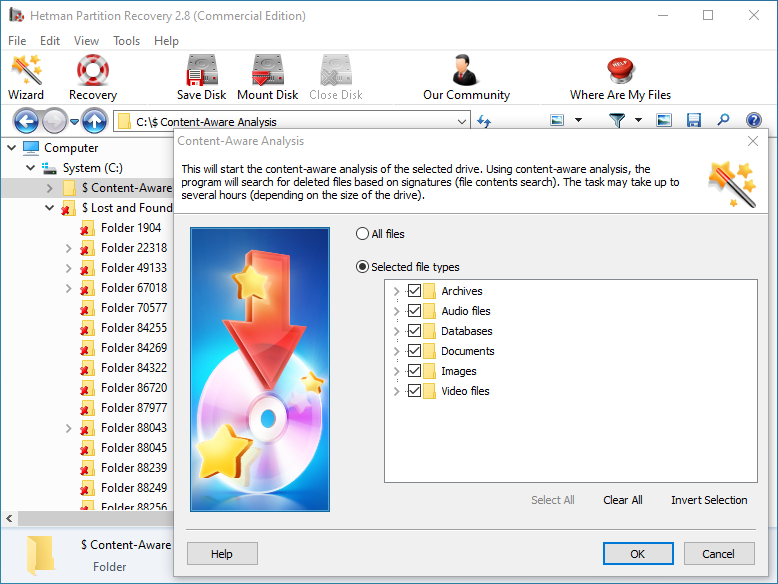

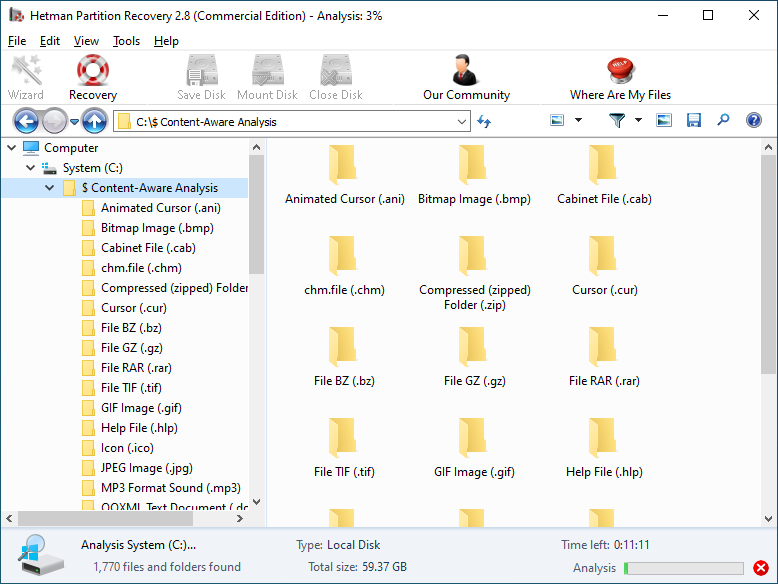

Double-click on the disk from which you need to recover ".NC" files, and select analysis type.

-

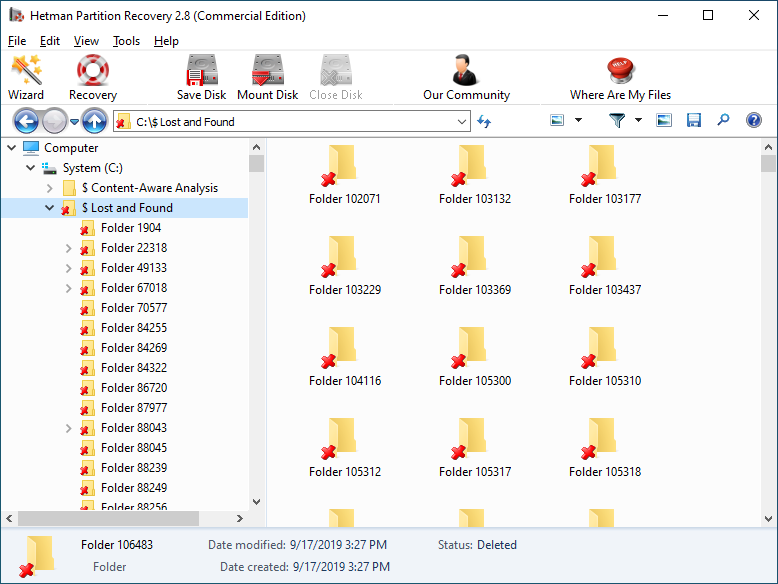

When the scanning is over, you will be shown the files for recovery.

-

To find a file you need, use the program’s interface to open the folder it was deleted from, or go to the folder "Content-Aware Analysis" and select the required file type.

-

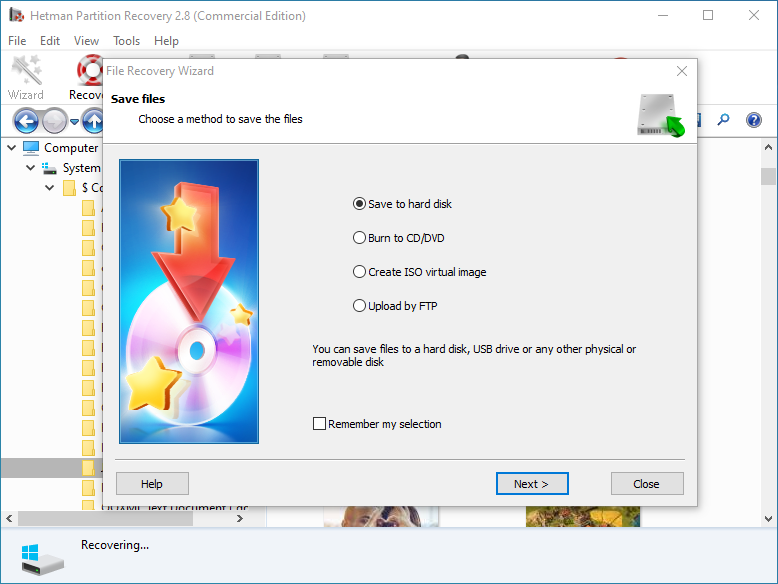

Select the files you have been looking for and click "Recovery".

-

Choose one of the methods for saving the files and recover them.

How to open file with ".NC" extension?

Looking for how to open a stereo mastercam Numerical Control File image file file?

Programs that open ".NC" files

| Windows |

|---|

|

|

Additional Information

-

File type: Mastercam Numerical Control File

-

File extension: .NC

-

Developer: CNC Software

-

Category: CAD Files

-

Format: Binary

-

File types that use the extension .NC:

Mastercam Numerical Control File

mcrypt Encrypted File

NetCDF File